Moderators: TomKerekes, dynomotion

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 12:36 am

now that my lathe works with Kmotion cnc i cant use the old mach3 PP because of the incremental thing

anyone know the closest PP to choose from there drop down?

i need this code converted over if possible

Code: Select all

N20 G20 G18 G64 G80 G90 M49 G40 G49

N30 m3s1200

N40 g04p2

N60 M08

N70 G0 Z0.0

N100 G97 S1800

N110 M03 G95 F0.005

N120 G40

N130 G01 X0.28 Z0.0

N140 G01 X0.26 Z0.0

N150 X0.26 Z-0.5095

N160 G02 X0.263 Z-0.52 I0.243 K-0.52

N170 G01 X0.263 Z-0.6104

N180 G02 X0.26 Z-0.621 I0.243 K-0.6104

N190 G01 X0.26 Z-5.5776

N200 G03 X0.2763 Z-5.5911 I0.3795 K-5.4497

N210 G02 X0.28 Z-5.5946 I0.2645 K-5.6072

N220 G01 X0.28 Z-5.7643

N230 G02 X0.2674 Z-5.7737 I0.2595 K-5.75

N240 G01 X0.26 Z-5.7762

N250 X0.26 Z-5.8388

N260 X0.2674 Z-5.8413

N270 G02 X0.28 Z-5.8507 I0.2595 K-5.865

N280 G01 X0.28 Z-6.0343

N290 G02 X0.2674 Z-6.0437 I0.2595 K-6.02

N300 G01 X0.26 Z-6.0462

N310 X0.26 Z-6.1088

N320 X0.2674 Z-6.1113

N330 G02 X0.28 Z-6.1207 I0.2595 K-6.135

N340 G01 X0.28 Z-6.3184

N350 G02 X0.26 Z-6.3369 I0.2445 K-6.3

N360 G01 X0.26 Z-6.35

N370 G00 X0.38 Z-6.35

N380 X0.38 Z-0.42 f0.009

N390 G01 X0.243 Z-0.42

N400 G02 X0.24 Z-0.4305 I0.223 K-0.42

N410 G01 X0.24 Z-0.4979

N420 X0.2494 Z-0.501

N430 G02 X0.263 Z-0.52 I0.243 K-0.52

N440 G01 X0.263 Z-0.6104

N450 G02 X0.257 Z-0.6247 I0.243 K-0.6104

N460 G03 X0.24 Z-0.644 I0.3795 K-0.7497

N470 G01 X0.24 Z-5.5554

N480 G03 X0.2763 Z-5.5911 I0.3795 K-5.4497

N490 G02 X0.28 Z-5.5946 I0.2645 K-5.6072

N500 G01 X0.28 Z-5.7643

N510 G02 X0.2674 Z-5.7737 I0.2595 K-5.75

N520 G01 X0.24 Z-5.7829

N530 X0.24 Z-5.8321

N540 X0.2674 Z-5.8413

N550 G02 X0.28 Z-5.8507 I0.2595 K-5.865

N560 G01 X0.28 Z-6.0343

N570 G02 X0.2674 Z-6.0437 I0.2595 K-6.02

N580 G01 X0.24 Z-6.0529

N590 X0.24 Z-6.1021

N600 X0.2674 Z-6.1113

N610 G02 X0.28 Z-6.1207 I0.2595 K-6.135

N620 G01 X0.28 Z-6.3184

N630 G02 X0.2572 Z-6.3379 I0.2445 K-6.3

N640 G01 X0.2545 Z-6.3388

N650 X0.2545 Z-6.35

N660 G00 X0.38 Z-6.35

N670 X0.38 Z-0.439

N680 G01 X0.2294 Z-0.439

N690 X0.22 Z-0.4421

N700 X0.22 Z-0.4912

N710 X0.2494 Z-0.501

N720 G02 X0.263 Z-0.52 I0.243 K-0.52

N730 G01 X0.263 Z-0.6104

N740 G02 X0.257 Z-0.6247 I0.243 K-0.6104

N750 G03 X0.22 Z-0.6777 I0.3795 K-0.7497

N760 G01 X0.22 Z-5.5217

N770 G03 X0.2763 Z-5.5911 I0.3795 K-5.4497

N780 G02 X0.28 Z-5.5946 I0.2645 K-5.6072

N790 G01 X0.28 Z-5.7643

N800 G02 X0.2674 Z-5.7737 I0.2595 K-5.75

N810 G01 X0.2203 Z-5.7895

N820 G03 X0.22 Z-5.79 I0.246 K-5.805

N830 G01 X0.22 Z-5.825

N840 G03 X0.2203 Z-5.8255 I0.246 K-5.81

N850 G01 X0.2674 Z-5.8413

N860 G02 X0.28 Z-5.8507 I0.2595 K-5.865

N870 G01 X0.28 Z-6.0343

N880 G02 X0.2674 Z-6.0437 I0.2595 K-6.02

N890 G01 X0.2203 Z-6.0595

N900 G03 X0.22 Z-6.06 I0.246 K-6.075

N910 G01 X0.22 Z-6.095

N920 G03 X0.2203 Z-6.0955 I0.246 K-6.08

N930 G01 X0.24 Z-6.1021

N940 G00 X0.38 Z-6.1021

N950 X0.38 Z-0.4421

N960 G01 X0.22 Z-0.4421

N970 X0.2 Z-0.4488

N980 X0.2 Z-0.4845

N990 X0.2494 Z-0.501

N1000 G02 X0.263 Z-0.52 I0.243 K-0.52

N1010 G01 X0.263 Z-0.6104

N1020 G02 X0.257 Z-0.6247 I0.243 K-0.6104

N1030 G03 X0.205 Z-0.7368 I0.3795 K-0.7497

N1040 G01 X0.205 Z-5.4627

N1050 G03 X0.2763 Z-5.5911 I0.3795 K-5.4497

N1060 G02 X0.28 Z-5.5946 I0.2645 K-5.6072

N1070 G01 X0.28 Z-5.7643

N1080 G02 X0.2674 Z-5.7737 I0.2595 K-5.75

N1090 G01 X0.2203 Z-5.7895

N1100 G03 X0.216 Z-5.805 I0.246 K-5.805

N1110 G01 X0.216 Z-5.81

N1120 G03 X0.2203 Z-5.8255 I0.246 K-5.81

N1130 G01 X0.2674 Z-5.8413

N1140 G02 X0.28 Z-5.8507 I0.2595 K-5.865

N1150 G01 X0.28 Z-6.0343

N1160 G02 X0.2674 Z-6.0437 I0.2595 K-6.02

N1170 G01 X0.2203 Z-6.0595

N1180 G03 X0.216 Z-6.075 I0.246 K-6.075

N1190 G01 X0.216 Z-6.08

N1200 G03 X0.22 Z-6.095 I0.246 K-6.08

N1210 G00 X0.38 Z-6.095

N1220 X0.28 Z-6.095

N1230 X0.28 Z0.0

N1240 G97 S1400

N1250 G95

N1260 X0.5 Z0.0

N1270 G00 X0.5 Z0.0 G95

N1280 G97 S1400

N1290 G95

N1300 X0.283 Z0.0

N1310 G41

N1320 G01 X0.233 Z0.0 F0.004

N1330 X0.233 Z-0.42

N1340 G02 X0.2262 Z-0.4295 I0.223 K-0.42

N1350 G01 X0.19 Z-0.4416

N1360 X0.19 Z-0.4917

N1370 X0.2462 Z-0.5105

N1380 G02 X0.253 Z-0.52 I0.243 K-0.52

N1390 G01 X0.253 Z-0.6104

N1400 G02 X0.25 Z-0.6176 I0.243 K-0.6104

N1410 G03 X0.195 Z-0.7364 I0.3795 K-0.7497

N1420 G01 X0.195 Z-5.463

N1430 G03 X0.2704 Z-5.5991 I0.3795 K-5.4497

N1440 G02 X0.2745 Z-5.6072 I0.2645 K-5.6072

N1450 G01 X0.2745 Z-5.75

N1460 G02 X0.2643 Z-5.7642 I0.2595 K-5.75

N1470 G01 X0.214 Z-5.7811

N1480 G03 X0.206 Z-5.805 I0.246 K-5.805

N1490 G01 X0.206 Z-5.81

N1500 G03 X0.214 Z-5.834 I0.246 K-5.81

N1510 G01 X0.2643 Z-5.8508

N1520 G02 X0.2745 Z-5.865 I0.2595 K-5.865

N1530 G01 X0.2745 Z-6.02

N1540 G02 X0.2643 Z-6.0342 I0.2595 K-6.02

N1550 G01 X0.214 Z-6.0511

N1560 G03 X0.206 Z-6.075 I0.246 K-6.075

N1570 G01 X0.206 Z-6.08

N1580 G03 X0.214 Z-6.104 I0.246 K-6.08

N1590 G01 X0.2643 Z-6.1208

N1600 G02 X0.2745 Z-6.135 I0.2595 K-6.135

N1610 G01 X0.2745 Z-6.3

N1620 G02 X0.254 Z-6.3285 I0.2445 K-6.3

N1630 G01 X0.2445 Z-6.3316

N1640 X0.2445 Z-6.35

N1650 G40

N1660 G00 X0.5 Z-6.35

N1670 G00 X0.5 Z0.0 G95

; TOOL definition

N1690 G0 Z0.0

N1700 ( Thread cutting tool )

N1710 M06 T0202

N1720 G97 S800

N1730 G95

N1740 g04p2

N1750 G97 S800

N1760 G95

N1770 X0.285 Z0.02

N1780 X0.235 Z0.02

N1790 G01 X0.228 Z0.02 F0.05

N1800 G32 X0.228 Z-0.45

N1810 G00 X0.285 Z-0.45 G95

N1820 X0.285 Z0.02

N1830 X0.235 Z0.02

N1840 G01 X0.2252 Z0.02 F0.05

N1850 G32 X0.2252 Z-0.45

N1860 G00 X0.285 Z-0.45 G95

N1870 X0.285 Z0.02

N1880 X0.235 Z0.02

N1890 G01 X0.223 Z0.02 F0.05

N1900 G32 X0.223 Z-0.45

N1910 G00 X0.285 Z-0.45 G95

N1920 X0.285 Z0.02

N1930 X0.235 Z0.02

N1940 G01 X0.2211 Z0.02 F0.05

N1950 G32 X0.2211 Z-0.45

N1960 G00 X0.285 Z-0.45 G95

N1970 X0.285 Z0.02

N1980 X0.235 Z0.02

N1990 G01 X0.2194 Z0.02 F0.05

N2000 G32 X0.2194 Z-0.45

N2010 G00 X0.285 Z-0.45 G95

N2020 X0.285 Z0.02

N2030 X0.235 Z0.02

N2040 G01 X0.218 Z0.02 F0.05

N2050 G32 X0.218 Z-0.45

N2060 G00 X0.285 Z-0.45 G95

N2070 X0.285 Z0.02

N2080 X0.235 Z0.02

N2090 G01 X0.2166 Z0.02 F0.05

N2100 G32 X0.2166 Z-0.45

N2110 G00 X0.285 Z-0.45 G95

N2120 X0.285 Z0.02

N2130 X0.235 Z0.02

N2140 G01 X0.2153 Z0.02 F0.05

N2150 G32 X0.2153 Z-0.45

N2160 G00 X0.285 Z-0.45 G95

N2170 X0.285 Z0.02

N2180 X0.235 Z0.02

N2190 G01 X0.2141 Z0.02 F0.05

N2200 G32 X0.2141 Z-0.45

N2210 G00 X0.285 Z-0.45 G95

N2220 X0.285 Z0.02

N2230 X0.235 Z0.02

N2240 G01 X0.213 Z0.02 F0.05

N2250 G32 X0.213 Z-0.45

N2260 G00 X0.285 Z-0.45 G95

N2270 X0.285 Z0.02

N2280 X0.235 Z0.02

N2290 G01 X0.213 Z0.02 F0.05

N2300 G32 X0.213 Z-0.45

N2310 G00 X0.285 Z-0.45 G95

N2320 X0.285 Z0.02

N2330 X0.235 Z0.02

N2340 G01 X0.213 Z0.02 F0.05

N2350 G32 X0.213 Z-0.45

N2360 G00 X0.285 Z-0.45 G95

N2370 X0.285 Z0.02

N2380 X0.235 Z0.02

N2390 G01 X0.213 Z0.02 F0.05

N2400 G32 X0.213 Z-0.45

N2410 G00 X0.285 Z-0.45 G95

N2420 X0.285 Z0.02

N2440 G00 X0.5 Z0.0 G95

N2450 M05 M30 m09

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 1:58 am

does this look alright?

Code: Select all

TITLE:

:T1 = {

MACH3 CNC Milling Controller

Copyright (c) 2003 Dolphin CADCAM Ltd

Modified to remove quadrant splitting in Arcs. nov 2013 mmm.

}

END:

WORDS:

:TMP = {DDDDDD.dd}

:BLOCK = {"N"DDDD}

:XAXIS = {"X"DDDDD.ddd} {"X"DDD.dddd}

:YAXIS = {"Y"DDDDD.ddd} {"Y"DDD.dddd}

:ZAXIS = {"Z"DDDDD.ddd} {"Z"DDD.dddd}

:XARC = {"I"DDDDD.ddd} {"I"DDD.dddd}

:YARC = {"J"DDDDD.ddd} {"J"DDD.dddd}

:DELAY = {"G04X"DDDDD.ddd}

:DWELL = {"P"DDDD.ddd}

:PECK = {"Q"DDDDD.ddd} {"Q"DDD.dddd}

:RPLANE = {"R"DDDDD.ddd} {"R"DDD.dddd}

:FEED = {"F"DDDDD.dddI} {"F"DDD.dddd}

:SPIN = {"S"DDDD}

:TOOL = {"T"DD}

:SUBPR = {"P"DDDD}

:REPEAT = {"L"DDDD}

:CRC = {"D"DD}

:TLC = {"H"DD}

:INDEX = {"INDEX"DDD.ddd}

:PROGNO = {"O"DDDDD}

END:

GROUPS:

:G1 = { G00 G01 G02 G03 }

:G8 = { G73 G74 G76 G80 G81 G82 G83 G84 G85 G86 G87 G88 G89 }

:G2 = { G17 G18 G19 }

:G3 = { G90 G91 }

:G4 = { G94 G95 }

:G5 = { G20 G21 }

:G6 = { G40 G41 G42 }

:G7 = { G43 G44 G49 }

:G9 = { G98 G99 }

:G10 = { G54 G55 G56 G57 G58 G59 }

:M1 = { M00 M01 M03 M04 M05 M06 }

:M2 = { M98 M99 }

END:

CYCLES:

DRILL CANNED

DRILLDWELL CANNED

DEEPDRILL EXPAND

NDEEP CANNED

NPECK CANNED

PECKDRILL EXPAND

NPECK CANNED

REAM CANNED

BORE CANNED

TAP CANNED

TAPNOREV EXPAND

LHTAP EXPAND

LHTAPNOREV EXPAND

HELIX VECTOR

END:

MACROS:

#N = { $BLOCK:BLOCK

IF ($BLOCK EQ 9995) THEN SET $BLOCK = 5

ENDIF }

#L = { [RAPID ? (G01) / (G00)] }

#FTYPE = { [FEEDTYPE ? (G94) / (G95) ] }

#X = { ($X:XAXIS) }

#Y = { ($Y:YAXIS) }

#Z = { ($Z:ZAXIS) }

#IINC = { ($XCEN-$OLDX):XARC }

#JINC = { ($YCEN-$OLDY):YARC }

#IABS = { $XCEN:XARC }

#JABS = { $YCEN:YARC }

#R = { ($CCLDIST:RPLANE) }

#P = { if ( $CDELAY ne 0 ) then ($CDELAY:DWELL) endif }

#F = { [RAPID ? [FEEDTYPE ? ($FPM:FEED) / ($FPR:FEED) ] ] }

#DWELL = { if ($CDELAY ne 0) then (G82) else (G81) endif }

#DWREM = { if ($CDELAY ne 0) then (G89) else (G85) endif }

#DWBOR = { if ($CDELAY ne 0) then (G88) else (G86) endif }

#RAPID = { SET [RAPID] = 2 }

#FEED = { SET [RAPID] = 1 }

#IPLANE = { if ( [CRETRACT] eq 2 ) then

(G99)

else

(G98)

endif }

#CRCX = { [CUTCOM ? (G40) / (G41) / (G42)] }

#CRCNOX = { [CUTCOM ? NULL / ($CRCNO:CRC) / ($CRCNO:CRC) ] }

#CRC = { NULL }

#CRCNO = { NULL }

#Q = { (ABS($CD1):PECK) }

END:

RULES:

:INIT = {

SET $USR1 = 0

SET $USR5 = 2.5

SET $BLOCK = 1

set $INCR = 1

set $RAPIDFEED = 10000 ; rapid feedrate

}

:PARTNO = { "( Produced :- " $TIME " " $DATE " )" EOB

"( CNC File :- " $CNCNAME " )" EOB

"( Post Processor :- " $POST " )" EOB

"( Part Number ID :- " $JOBTEXT " )" EOB

}

:XPROGNO = { "%" EOB $PROGNO:PROGNO EOB }

:UNITS = { #N (G00) [UNITS ? (G21) / (G20)] (G17) (G90)

(G40) (G49) (G80) EOB

IF ([UNITS] EQ 1) THEN

SET $USR2 = 0.0005

set $PRECISION = 0.001

ELSE

SET $USR2 = 0.00005

set $PRECISION = 0.0001

ENDIF

}

:STOP = { UNSETALL

#N (M00) EOB

}

:OPSTOP = { UNSETALL

#N (M01) EOB

}

:PPRINT = { #N $JOBTEXT EOB }

:RETRACT = { #N (G00) #Z eob }

:GOTO = {

SET $USR3 = 0

IF ((ABS($DELTAX) GE $USR2) OR (ABS($DELTAY) GE $USR2)) THEN

SET $USR3 = 1

ENDIF

IF (($USR3 EQ 1) OR (ABS($DELTAZ) GE $USR2)) THEN

#N #L #CRC

IF ((ABS($DELTAX) GE $USR2) OR (ABS($DELTAY) GE $USR2)) THEN

$X:XAXIS $Y:YAXIS

ENDIF

IF (ABS($DELTAZ) GE $USR2) THEN

#Z

ENDIF

#CRCNO #F EOB

ENDIF

}

:GOCLW = { #N (G02) #CRC #X #Y #Z #IINC #JINC #CRCNO #F eob }

:GOACLW = { #N (G03) #CRC #X #Y #Z #IINC #JINC #CRCNO #F eob }

:DELAY = { #N $DELAY:DELAY eob }

:SPINDLE = { #N $SPINDLE:SPIN [SPIN ? NULL / (M03) / (M04) ] eob

#N #FTYPE EOB }

:FINISH = { #N (M09) EOB

#N (M30) EOB "%" EOB }

:SELCTL = {

IF ($USR1 EQ 1) THEN

#N (M09) EOB

ENDIF

SET $USR1 = 1

UNSETALL

set $CYCLETIME = $CYCLETIME + 0.5 ; 30 seconds for a tool change

if ( $Z ne $ZTLOAD ) then

#N (G00) (G28) $ZTLOAD:ZAXIS eob

#N (G49) EOB

endif

#N (G49) eob

#N $TOOLNO:TOOL (M06) " ( " $JOBTEXT " )" eob

#N (G00) (G43) $CLEARP:ZAXIS $TLCNO:TLC eob }

:DRILL = { #N #IPLANE #DWELL #X #Y #Z #R

IF ($CDELAY NE 0) THEN

($CDELAY:DWELL)

ENDIF

#F eob }

:BORE = { #N #IPLANE #DWBOR #X #Y #Z #R

IF ($CDELAY EQ 0) THEN

($USR5:DWELL)

ELSE

($CDELAY:DWELL)

ENDIF

#F eob }

:REAM = { #N #IPLANE #DWREM #X #Y #Z #R #F EOB }

:TAP = {#N #IPLANE (G84) #X #Y #Z #R #F EOB }

:NPECK = { #N #IPLANE (G83) #X #Y #Z #Q #R #F EOB }

:NDEEP = { #N #IPLANE (G83) #X #Y #Z #Q #R #F EOB }

:DRILLDWELL = :DRILL

:COOLANT = {IF ([COOLANT] EQ 1) THEN

#N (M09) EOB

ENDIF

IF ([COOLANT] EQ 2) THEN

#N (M08) EOB

ENDIF

}

:CYCLEOFF = {

#N (G80) EOB

UNSET (G8)

unset :RPLANE

unset :PECK

UNSET (G9)

UNSET :FEED

UNSET :ZAXIS

UNSET :DWELL

}

:GOHOME = { if ( $Z lt $CLEARP ) then

#N (G00) (G80) $CLEARP:ZAXIS eob

endif

#N (G00) $XSAFPOS:XAXIS $YSAFPOS:YAXIS EOB

#N (G00) (G28) $ZSAFPOS:ZAXIS eob

#N (G49) EOB }

:CLEARP = {

if ($CLEARP lt $CLDIST) then

ERRMSG "Clear plane is below Wsurf - DANGER"

endif

}

END:

-

TomKerekes

- Posts: 2540

- Joined: Mon Dec 04, 2017 1:49 am

Post

by TomKerekes » Wed Jul 24, 2019 5:22 pm

Hi turbothis,

now that my lathe works with Kmotion cnc i cant use the old mach3 PP because of the incremental thing

what incremental thing? Arc centers?

The post processor helps convert CAD data to GCode. It doesn't really convert GCode.

You might start with a simple example first.

It doesn't look to me like that Post Processor supports Arcs in the XZ plane. Only XY. I see:

#IINC = { ($XCEN-$OLDX):XARC }

#JINC = { ($YCEN-$OLDY):YARC }

for I and J but nothing for K. Also

:XARC = {"I"DDDDD.ddd} {"I"DDD.dddd}

:YARC = {"J"DDDDD.ddd} {"J"DDD.dddd}

for X and Y but not Z.

Regards,

Tom Kerekes

Dynomotion, Inc.

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 5:57 pm

sorry for the confusion, this is just a hot mess tying it all together

i will punch in X and Z axis info and see what it does....

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 7:25 pm

this one almost works but seems wonky on the X Y I K parameters

Code: Select all

TITLE:

:T1 = {

CNC Lathe

Mach3 Radius Mode Post

G32 type threading

Modified by Steve Blackmore 06/04/05

}

:T2 = {

Added Mach3 Constant surface speed support 30/01/05

Added G83 peck drilling 02/03/05

New tool format support added 27/07/05

Altered M6 to follow tool select 24/12/05

Modified by Steve Blackmore

}

END:

VERSION:

FILEVERSION 11.0 TURNING

END:

WORDS:

:TMP = {DDDDDD.dd}

:BLOCK = {"N"DDDD" "}

:XAXIS = {"Z"DDDDD.ddd" "} {"Z"DDD.dddd" "}

:YAXIS = {"X"DDDDD.ddd" "} {"X"DDD.dddd" "}

:XARC = {"K"DDDDD.ddd" "} {"K"DDD.dddd" "}

:YARC = {"I"DDDDD.ddd" "} {"I"DDD.dddd" "}

:ARAD = {"R"DDDDD.ddd" "} {"R"DDD.dddd" "}

:DELAY = {"G04 P"DDD" "}

:DWELL = {"P"DDDD.dddd" "}

:PECK = {"Q"DDDDD.ddd" "} {"Q"DDD.dddd" "}

:NDEEP = {"Q"DDDDD.ddd" "} {"Q"DDD.dddd" "}

:RPLANE = {"R"DDDDD.ddd" "} {"R"DDD.DDDD" "}

:FEED = {"F"DDDDD.dddI" "} {"F"DDD.dddd" "}

:SPIN = {"S"DDDD" "}

:TOOL = {"T"ZDD}

:SUBPR = {"P"DDDD" "}

:REPEAT = {"L"DDDD" "}

:CRC = {"D"DD" "}

:TLC = {""ZDD" "}

:SURF = {"S"DDDD" "}

:SRAD = {"R"DDDD.ddI} {"R"DD.ddddI}

:INDEX = {"INDEX"DDD.ddd" "}

:PROGNO = {"O"DDDDD" "}

:NUM1 = {" "DDDD.dddd" "}

:ROT = {" "DD" "}

:TOOLD = {DDDDD.ddd} {DDD.dddd}

END:

AXES:

YSCALE 1

TURRET

END:

GROUPS:

:G1 = {G00_ G01_ G02_ G03_ G80_ G81_ G82_ G83_ G83.1_ G84_ G85_ G86_ G87_ G88_ G89_}

:G2 = {G17_ G18_ G19_}

:G3 = {G90_ G91_ G90.1_ G91.1_}

:G5 = {G48_ G93_ G94_ G95_ G96_ G97_}

:G6 = {G20_ G21_}

:G7 = {G40_ G41_ G42_}

:G8 = {G43_ G49_}

:G10 = {G98_ G99_}

:G12 = {G50_ G51_ G54_ G55_ G56_ G57_ G58_ G59_ G59.1_ G59.2_ G59.3_}

:G13 = {G61_ G61.1_ G64_}

:G4 = {M00_ M01_ M02_}

:G7 = {M03_ M04_ M05_}

:G8 = {M07_ M08_ M09_}

:G9 = {M48_ M49_}

END:

CYCLES:

NPECK CANNED

NDEEP CANNED

TURN EXPAND

FACE EXPAND

THREAD EXPAND

END:

MACROS:

#N = {

$BLOCK:BLOCK

; If the block number reaches the max (according to RD274) start over

; Note: 'N' has no meaning in processing and is there for readability ONLY

IF ($BLOCK EQ 99990) THEN

SET $BLOCK = 5

ENDIF

}

#L = { [RAPID ? (G01_) / (G00_)] }

#FTYPE = { [FEEDTYPE ? (G94_) / (G95_) ] }

#X = { $X:XAXIS }

#Y = { $Y:YAXIS }

#I = { $XCEN:XARC }

#K = { $YCEN:YARC }

#AR = { $ARCRAD:ARAD }

#R = { ($CCLDIST:RPLANE) }

#P = { IF ($CDELAY NE 0) THEN ($CDELAY:DWELL) ENDIF }

#F = { [RAPID ? [FEEDTYPE ? ($FPM:FEED) / ($FPR:FEED)] ] }

#DWELL = { IF ($CDELAY NE 0) THEN (G82_) ELSE (G81_) ENDIF }

#RAPID = { SET [RAPID] = 2 }

#FEED = { SET [RAPID] = 1 }

#SPIN = { ($SPINDLE:SPIN) [SPIN ? (M05_) / (M03_) / (M04_) ] }

#SURF = { IF ( $SURF GT 1) THEN

$SURF:SURF

ELSE "S525"

ENDIF

}

#GCLW = {

IF ($USR11 EQ 0) THEN

(G02_)

ELSE

(G03_)

ENDIF

}

#GACLW = {

IF ($USR11 EQ 0) THEN

(G03_)

ELSE

(G02_)

ENDIF

}

#IPLANE = {

IF ([CRETRACT] EQ 2) THEN

(G99_)

ELSE

(G98_)

ENDIF

}

#CRC = {

; Only output G41/G42 if part surface is requested (PSPROG=2) which means the CNC

; has to offset the tool

IF ([PSPROG] EQ 2) THEN

[CUTCOM ? (G40_) / (G41_) / (G42_) ]

ENDIF

}

#CRCNO = {

IF ([PSPROG] EQ 2) THEN

($CRCNO:CRC)

ENDIF

}

#Q = { ABS($CDEPTH/$CNDEPTH):NDEEP }

#Q = { ABS($CDEPTH/$CNDEPTH):NPECK }

#UNSET = {

IF ((ABS($DELTAX) LT $USR8) AND (ABS($DELTAY) LT $USR8)) THEN

UNSETALL

ENDIF

}

END:

RULES:

:INIT = {

set $RAPIDFEED = 100 ; rapid feedrate

SET $USR11 = 0 ; Set to 1 if Proturn Arcs to be negated (dependant on tool)

SET $USR12 = 0 ; set for Arc direction fix for FRONT turret and TURN cycles.

SET $USR13 = 1.0 ; SCALE FACTOR TO COMPENSATE FOR ANGLES BEING WRONGLY SCALED IN INCH.

SET $USR14 = 0.0

}

:START = {

; start with N10, increment in 10s

SET $BLOCK = 10

set $INCR = 10

}

:ORIGIN = {

;#N (G92_) $ORIGINY:YAXIS $ORIGINX:XAXIS EOB

;unset :XAXIS

;unset :YAXIS

}

:PPRINT = { #N "; (" $JOBTEXT ")" EOB }

:RETRACT = { #N #L #Y #X EOB }

:INSERT = { #N ";" $JOBTEXT EOB }

:PARTNO = { ";" "(" $JOBTEXT ")" EOB }

:UNITS = {

; G20/G21 = Inch/MM units

; G18 = XZ Plane

; G64 = Constant velocity mode (G61 = exact stop)

; G80 = Cancel modal motion (deactivates all move modalities)

; G90 = Absolute mode (G91 = Incremental mode)

; M49 = Disable speed/feed overrides

#N [UNITS ? (G21_) / (G20_)] (G18_) (G64_) (G80_) (G90_) (M49_) "G90.1 "

; KAA - changed order to default IN so that the set is not needed 2x for each IN

; Sets MIN change in move for a program block to be written

SET $USR8 = 0.00005 ; default IN scale

set $usr13 = 25.4

IF ([UNITS] EQ 1) THEN

SET $USR8 = 0.0005 ; set MM scale

SET $USR13 = 1.0

ENDIF

(G40_) (G49_) (G80_) EOB

#N #FTYPE #F EOB

}

:CUTCOM = {

IF (0 NE 0) THEN

; Only output G41/G42 if part surface is requested (PSPROG=2) which means the CNC

; has to offset the tool

IF ([PSPROG] EQ 2) THEN

[CUTCOM ? (G40_) / (G41_) / (G42_) ]

ELSE

(G40_)

ENDIF

#CRCNO EOB

ENDIF

}

:GOTO =

{

NULL ; "DISTANCE : " $DISTANCE:NUM1 EOB

IF ($DISTANCE GE $USR8) THEN

#N #CRC #CRCNO EOB

#N #L #Y #X #FTYPE #F EOB

ENDIF

}

:GOCLW = {

#UNSET

IF (([PSPROG] NE 2) OR ([CUTCOM] LT 2)) THEN

#N #CRC EOB

#N #GCLW #Y #X #AR #F EOB

ELSE

#N #CRC #CRCNO EOB

#N #GCLW #Y #X #AR #F EOB

ENDIF

}

:GOACLW = {

#UNSET

IF (([PSPROG] NE 2) OR ([CUTCOM] LT 2)) THEN

#N #CRC EOB

#N #GACLW #Y #X #AR #F EOB

ELSE

#N #CRC #CRCNO EOB

#N #GACLW #Y #X #AR #F EOB

ENDIF

}

:DELAY = { #N $DELAY:DELAY EOB }

:NDEEP = { #N (G83) #Y #X #R #Q #IPLANE #F EOB }

:NPECK = { #N (G83.1) #Y #X #R #Q #IPLANE #F EOB }

:SCREWING = { #N "G32 " #Y #X #F EOB

UNSET (G5)

UNSET :FEED

}

:SCRCUT = {

UNSET :FEED

#N #FTYPE #F EOB

#N (G0_) #X #Y EOB

#N (G1_) $CXSTART:XAXIS $CYSTART:YAXIS EOB

#N (G76_) ($CYEND-$CDEPTH):YAXIS $XEND:XAXIS ""$FEEDANGLE:PA " "$PITCH:FS " "$ROUGHCUTS:DS " "$FINISHCUTS:PF " T0 " $SPINDLE:SPIN ""$CLDIST:PO eob

#N (G94_)eob

UNSET :FEED

}

:SPINDLE = {UNSET (G5)

IF ( [SPIN] eq 1) then

#N (M05) eob

ENDIF

IF ([SPINTYPE] EQ 2 ) THEN

#N [SPIN ? NULL / (M03_) / (M04_) ] #FTYPE #F EOB

#N (G48_) $MAXSPIN:SPIN " " EOB

#N (G96_) $SURF:SURF EOB

ELSE

#N [SPIN ? NULL / (M03_) / (M04_) ] #FTYPE #F EOB

#N (G97_) $SPINDLE:SPIN " " EOB

ENDIF }

:FINISH = { #N (M05_) (M09_) EOB

#N (M30_) EOB " " EOB }

:TOOL = {UNSET :G5

"; TOOL definition" EOB

}

:SELCTL = {

SET $USR11 = 0

IF ([TURRET] EQ 2) THEN

SET $USR12 = 1 ; Front Turret, set $USR12 for TURN cycles arc direction

else

SET $USR12 = 0

ENDIF

set $CYCLETIME = $CYCLETIME + 0.5 ; 30 seconds for a tool change

#N (M09_) EOB

#N "G00"" " $YSAFPOS:YAXIS $XSAFPOS:XAXIS (M05_) EOB

IF ($X NE $XTLOAD ) THEN

#N (G28_) $XTLOAD:XAXIS EOB

#N (G49_) EOB

ELSE

IF ($Y NE $YTLOAD ) THEN

#N (G28_) $YTLOAD:YAXIS EOB

#N (G49_) EOB

ENDIF

ENDIF

EOB

#N (G49_) EOB

#N " ( " $JOBTEXT " )" EOB

#N $TOOLNO:TOOL $TLCNO:TLC"" EOB

}

:COOLANT = {

IF ([COOLANT] EQ 0) THEN

#N (M09_) EOB

ELSE

IF ([COOLANT] EQ 1) THEN

#N (M09_) EOB

ELSE

IF ([COOLANT] EQ 2) THEN

#N (M08_) EOB

ENDIF

ENDIF

ENDIF

}

:CYCLEOFF = {

#N (G80_) EOB

unset :G1

UNSET(M08_)

UNSET:RPLANE

UNSET(M09_)

UNSET :FEED

UNSET:YAXIS

UNSET:XAXIS

UNSET (G5)

UNSET :SPIN

UNSET :PECK

UNSET :DWELL

}

:GOHOME = {

UNSET (G5)

UNSET :FEED

UNSET :SPIN

#N "G00" " " $YSAFPOS:YAXIS $XSAFPOS:XAXIS #FTYPE #F EOB

}

END:

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 7:34 pm

i think it should be like this....

:XAXIS = {"X"DDDDD.ddd" "} {"X"DDD.dddd" "}

:ZAXIS = {"Z"DDDDD.ddd" "} {"Z"DDD.dddd" "}

:XARC = {"I"DDDDD.ddd" "} {"I"DDD.dddd" "}

:ZARC = {"K"DDDDD.ddd" "} {"K"DDD.dddd" "}

and ....

#I = { $XCEN-$OLD:XARC }

#K = { $ZCEN-$OLD:YARC }

-

TomKerekes

- Posts: 2540

- Joined: Mon Dec 04, 2017 1:49 am

Post

by TomKerekes » Wed Jul 24, 2019 7:49 pm

I think

#K = { $ZCEN-$OLD:YARC }

should be

#K = { $ZCEN-$OLD:ZARC }

Regards,

Tom Kerekes

Dynomotion, Inc.

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 8:02 pm

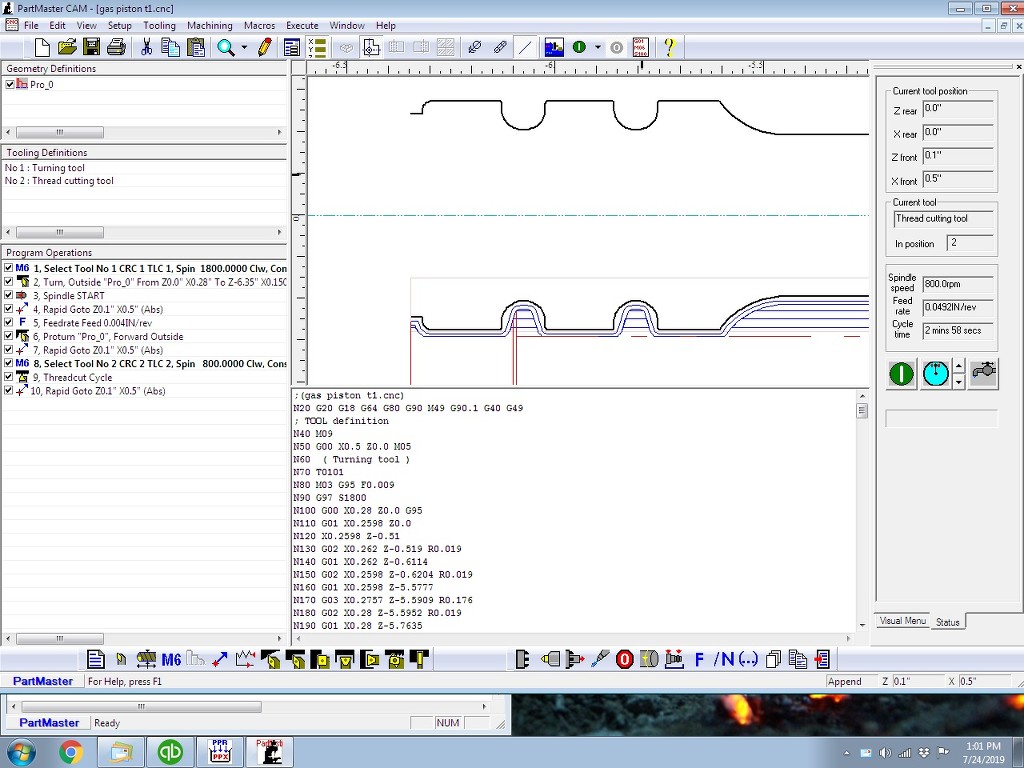

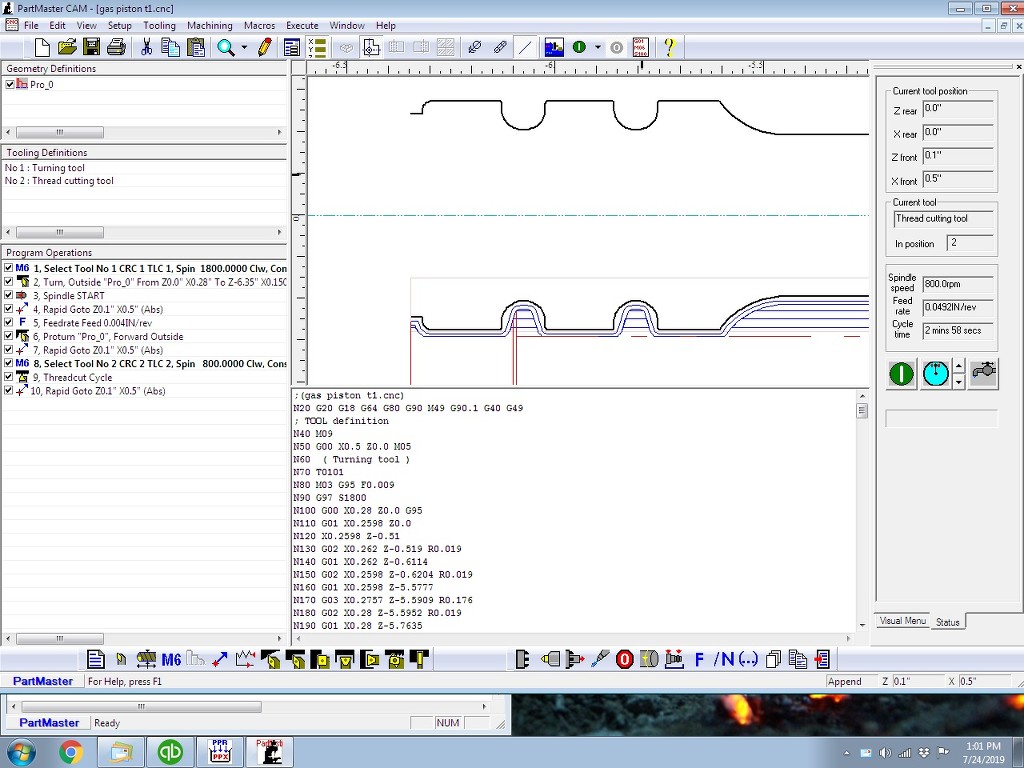

so far this is what i got

in the cam.....

and on the kmotioncnc......

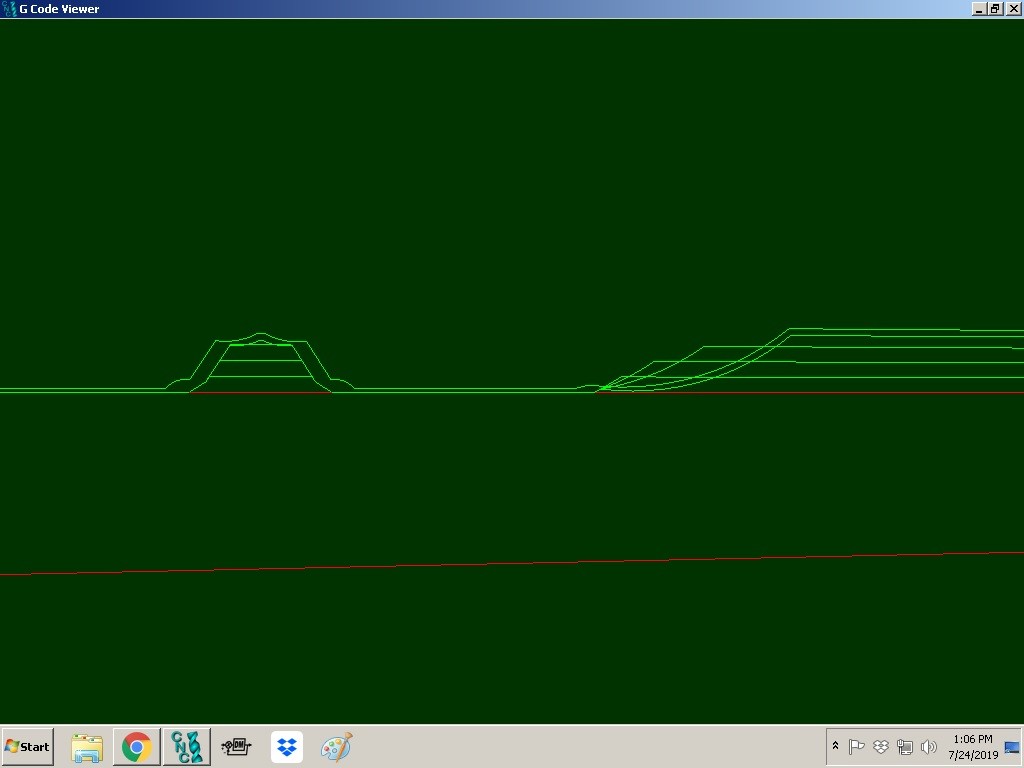

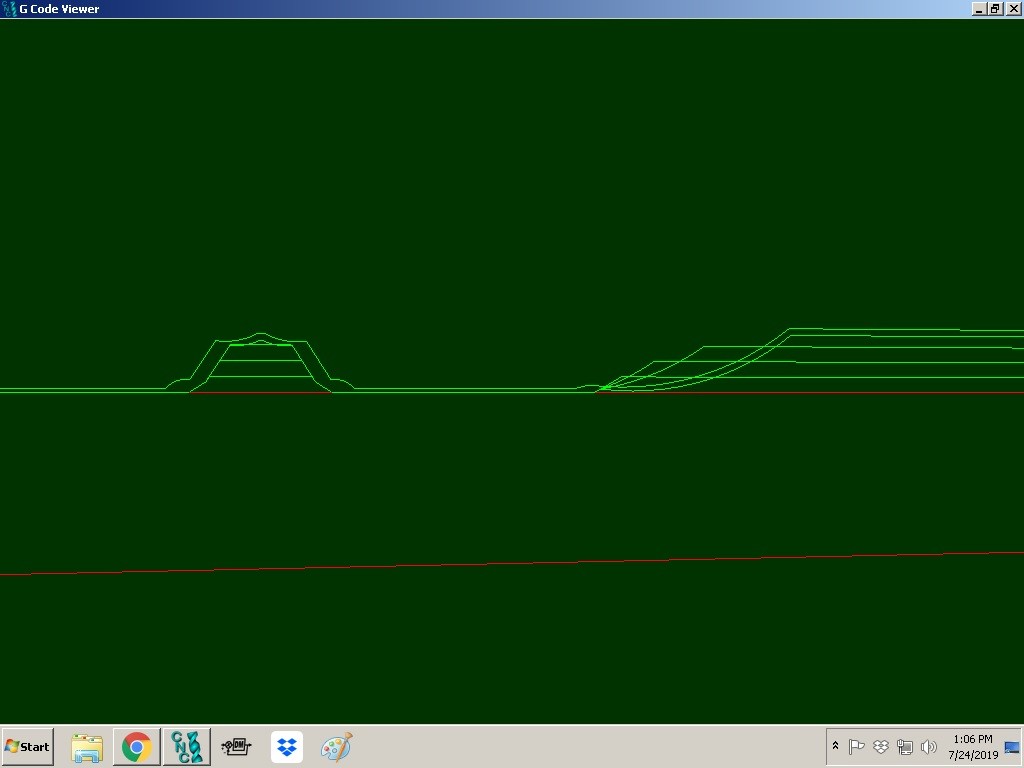

just some strange arc's in there!

-

turbothis

- Posts: 309

- Joined: Fri Mar 15, 2019 4:07 pm

- Location: southern oregon

Post

by turbothis » Wed Jul 24, 2019 8:06 pm

close up of the odd arc's

its like they are backwards?

-

TomKerekes

- Posts: 2540

- Joined: Mon Dec 04, 2017 1:49 am

Post

by TomKerekes » Wed Jul 24, 2019 8:53 pm

Looks like $USR11 can be changed to 1to reverse the Arcs

SET $USR11 = 0 ; Set to 1 if Proturn Arcs to be negated (dependant on tool)

Regards,

Tom Kerekes

Dynomotion, Inc.